what is the purpose of flue gas analyzer|flue gas analyzer meaning : Brand The primary purpose is to assess the efficiency of the combustion process and to monitor and reduce emissions of harmful pollutants. Flue gas analysers play a . Banco Itaú - Feito Para Você . conta .

{plog:ftitle_list}

16 de dez. de 2022 · Аватар: Путь воды (2022) PG-13 16/12/2022 (US) фантастика , приключения , боевик 3h 12m Рейтинг

A flue gas analyzer is an instrument used in HVAC (Heating, Ventilation, AC) systems to measure and analyze the composition of the gases that are produced as a result of combustion. A flue gas analyser shows the proportion of CO/CO2 in its exit flue and serves two purposes: Appliance Checking – By placing it in a furnace or exhaust fan, one can . The primary purpose is to assess the efficiency of the combustion process and to monitor and reduce emissions of harmful pollutants. Flue gas analysers play a . Flue gas analyzers are crucial for sustaining efficient combustion processes, managing emissions, and guaranteeing worker and environmental safety. By comprehending flue gas components and the role .

A flue gas analyser calculates the gas emissions from your appliances, informing you of their efficiency and safety. The term ‘flue gas’ refers to the gas emissions that are generated during the combustion process and .A flue gas analyzer is an instrument used in HVAC (Heating, Ventilation, AC) systems to measure and analyze the composition of the gases that are produced as a result of combustion. The appliance is designed to measure different variables, including carbon monoxide, oxygen, carbon dioxide, nitrogen oxides, and other components or pollutants .Nova manufactures continuous and portable analyzers for this purpose. A flue gas analyzer will enable you to measure the concentrations of various gases and adjust burners on a boiler to help achieve optimal combustion. Efficient .What is a Flue Gas Analyser? A flue gas analyser, also called an emissions analyser, or a stack analyser, is a specialized instrument used to measure the composition and concentration of gases emitted from combustion equipment .

A flue gas analyser is a useful measuring instrument for ensuring that the air in a building is safe. Some gases, like carbon monoxide, are very deadly, so significant amounts of these gases detected in the open air is a hazard. What flue gas analyser readings should be.An oxygen analyzer measures the amount of oxygen in the flue gas produced by the combustion process and compares it to the theoretical amount of oxygen needed for complete combustion. With accurate data, plant operators can make adjustments to the air-to-fuel ratio to achieve optimal combustion efficiency.What Is a Gas Analyzer? Real-time gas analysis enhances efficiency, safety, throughput, product quality, and ensures environmental compliance. Gas analysis utilizes various technologies such as tunable diode laser spectroscopy, zirconia oxygen analysis, infrared gas analysis, stack gas analysis, dust monitoring, process gas chromatography, continuous emissions monitoring .

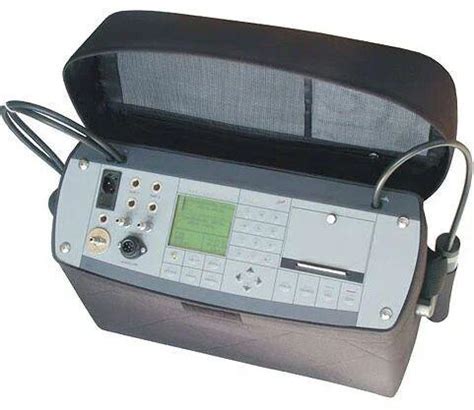

A gas analyzer is an instrument used to measure the concentrations of different gases in a sample. This type of device has many uses, such as measuring flue gas emissions from combustion sources, ambient air monitoring, safety analysis in industrial settings, and environmental research.Flue gas concentrations were measured using an E-Instruments (2003) 8000 Portable Flue Gas Analyzer capable of detecting CO, CO 2, NO x, SO 2, and O 2 in a flue gas stream. The analyzer uses electrochemical cells to detect flue gases in low range applications and NDIR in middle range applications. . There are also ideas for using heat pumps .What is a Portable Flue Gas Analyser? A portable electronic device, a flue gas analyser measures and displays the products of combustion from both domestic and commericial fossil fuelled appliances. Additionally, they can measure the ambient air quality in rooms or buildings. . This article briefly explains the purpose of analysers, what they .

The Testo flue gas analyzers with exchangeable, precalibrated flue gas sensors measure, analyse and document whether flue gas values are adhered. Irrespective of whether you carry out spot or long-term measurements, we offer a comprehensive range of gas sensors for the analysis of flue gases. Also known as flue gas analyzers, these detectors typically consist of an analyzer unit, a pump to draw gas samples, sensors to measure gas concentrations, a sample probe to collect flue gases, and filters to protect the sensors from particulates. . To select the best combustion analyzer that serves your purpose, follow this guide. To narrow .Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases, as from a fireplace, oven, furnace, boiler or steam generator. It often refers to the exhaust gas of combustion at power plants. Technology is available to remove pollutants from flue gas at power plants.Combustion Analyzer Resources Combustion Analyzer Application Advisor . Combustion analyzers are multifunction instruments designed to calculate the efficiency of all types of boilers, heaters and furnaces by measuring a range of parameters such as stack temperature, flue pressure and levels of gases.

online flue gas analyser

A flue gas analyser will show the ratio between Carbon Monoxide and Carbon Dioxide in the flue gases. When measuring a condensing boiler’s flue gases, unless specified otherwise by the manufacturer, this ratio should not exceed 0.004; likewise, the CO concentration should not be higher than 350 PPM. If the readings are higher, the appliance . Due to the nature of the typical toxic gas sensor used in a flue gas analyser, emissions gases and products of combustion can produce cross-sensitivity issues. Field failures can be dangerous and costly and lives depend on a good sensing technology. What is less widely recognised are the other economic benefits a gas sensor can bring, by .Using a Flue Gas Analyzer or any meter designed to measure oxygen or carbon-monoxide, and taking the flue gas temperature and the temperature of the combustion air, the following Table can be used to determine combustion efficiency when operating on natural gas. The Temperature Column is the NET Difference between Flue Gas and Combustion Air .testo 300+ smart flue gas analyser - the ultimate instrument for working on boilers. testo 550i app-operated digital manifold - commission and service heat pumps, as well as refrigeration and air conditioning systems. Two testo 115i .

> Only operate the product properly, for its intended purpose and within the parameters specified in the technical data. Do not use any force. . Flue gas analyser . Feature : Values . Storage and transport temperature -20 to 50 °C . Operating temperature -5 to 45 °C . Power supply :

Analyzer Kits - 4 Configured for typical combustion needs. Two gas: (O 2, CO) standard combustion kit; Three gas: (O 2, CO, NO) combustion kit for Boilers & Burners; Three gas: (O 2, CO, NO) Engine Testing Kit; Single gas upgrade with O 2 - Add what you need.; Built to last. Long life-time CO and NOx sensors (up to 5 years) make cost of ownership the best in market.

A flue gas analyzer is also used to measure the combustion levels in an internal combustion engine, such as those used in cars, trucks, tractors, generators (gensets) and other motorised equipment. All the essentials for combustion gas analysis . Si-CA 030.Depending on the condition, manufacturer or usage purpose calibration can take from 24-72 hours, on average. Due to the nature of the service, it’s very rare to get same-day flue gas analyser calibration. . Flue gas analyser calibration is essential in order to ensure fully accurate readings to keep yours and your customers’ appliances .

The analyzer then uses a mathematical model to determine the O 2 percentage based on the degree of attenuation. A zirconia sensor analyzer (Figure 3) is placed in a duct in the flue-gas stream. Gases from the duct diffuse across the filter media into the diffusion chamber based on gas partial pressure equalization mechanisms.DuraNOVA Gas Analyzers; Flue Gas & Emissions Analyzers; Landfill Gas Analyzers / Biogas Analyzers; Power Generation and Hydrogen Purity; . For living organisms, uptake of O2 from the air is the essential purpose of breathing. Oxygen plays a critical role in cellular respiration, which is the process of converting food into energy. .

The testo 320 LX flue gas analyzer is your compact, all-purpose tool for burners. The high-quality multi-function instrument guides you reliably through all the measurements which come up during the entire service life of a heating system. Its operation is self-explanatory, the choice of probes is comprehensive and the results are highly accurate.

Select from the list of Choices the word/phrase that correctly completes the statement below. Choices: • tube • fuel • combustion • carbon • dioxide • chemical • liquid • natural • gas • levels • tape • heat • continuous sampling • oxygen Listed below are three types of Flue Gas Analyzers: 1. _____ . example: Gastec system 2. _____ . example: Fyrite system 3 .

The purpose of this Guide is to provide the boiler owner the knowledge . The primary tool required to complete a boiler combustion tune-up is a flue gas analyzer. The required measurements for an appropriate flue gas analysis are flue gas oxygen content, combustibles content, and any components that are managed as a part .Purpose of O2 measurement in flue gas. The optimum ratio of fuel and combustion air requirement is found from oxygen measurement in the flue gas. An oxygen analyzer is a perfect instrument to monitor the amount of excess air and heat loss. To keep high combustion efficiency levels, oxygen and fuels must be measured. .

paint hatch test

handheld flue gas analyzer

Zona Leste 33 anos R$ 150. star Sexo c anal e local 170 chamada de vídeo 20 arthur alvim. Zona Leste 25 anos R$ 150. check Verificada. 511 garotas de programa na Zona Leste .

what is the purpose of flue gas analyzer|flue gas analyzer meaning